TECHNOLOGY – EQUIPMENT

Our expertise and equipment allows us to produce the latest wafer level CSP devices and BGA devices.

OUR MACHINERY

MY100LXe-10 is a high precision pick and place machine that enables manufacturing of low volume, quick turnaround products, thanks to it’s fast set-up and changeover capabilities. With a top speed of 16,000 components per hour and a feeder capacity of up to 176 parts, it is at the top end of its game. Ideal for fast changeover of jobs and components the Mycronic platform is the most flexible on the market.

The MY100LXe-10 has been designed as an all-in-one platform for electronics manufacturers. Adaptable and upgradeable, Mycronic’s machines are designed to grow with customers, should they require higher throughput.

This machine has built in component verification which is a key feature for contract manufacturing.

Manufactured in Sweden and renowned for high quality.

Switches effortlessly from full volume to batch size one. Handle a wider range of components with uncompromising production quality, total stock accuracy and complete traceability down to individual PCB serial number.

The MY300 delivers SMT pick-and-place at next level precision and flexibility in a fast, small and smart format.

Key benefits:

- Up to 192 feeder positions

- Top speed of 16,000 CPH

- Full component range in one machine

- Fastest set-ups and changeovers in the industry

- Capable of pin-in-paste, PoP, QFN, board cavities and more

- On-the-spot board revisions

- Handle short tape strips and non-standard carriers

- Electrical verification of resistors, capacitors, diodes and transistors (optional)

The Solano convection oven is DIMA’s answer to demanding LEAD FREE production processes.

Special designed process chambers transfer the heat with a minimum of stress for the components. Even with lead free applications temperatures stay below the critical component temperatures. This model is equipped with an additional edge conveyor.

The Solona has top and bottom heaters and a precise even heat flow.

Stronger, faster and more accurate than its predecessor. The New Reprint Mantis fully automatic screen printer sets new levels for productivity whilst maintaining an exceptional price to performance ratio. Aimed at medium to high users, and keeping the external looks of its predecessor. This totally new design is packed with highly automated and innovative features.

- Less than 12 sec’s cycle times.

- Unique vision alignment system.

- Improved Print Accuracy +/- 15 microns.

- Closed loop servo control of all moving platforms.

- Fully automatic vision system for precise, repeatable printing (+/- 10 microns)

Manufactured in the United Kingdom with local support.

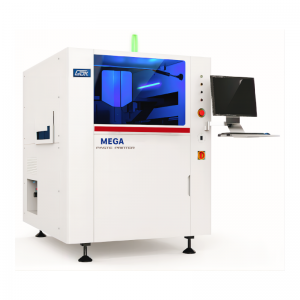

The Mega TSE3070T fully automatic SMT solder paste stencil printer provides a package of everything that is needed in a fully automatic in-line printer to produce high quality, high precision and high speed solder paste prints.

Key features:

- Fully adjustable in-line SMT solder paste printer

- Adjustable screen size (min 370mm x 370mm to 737mm / 29” x 737mm /29”

- Automatic conveyor width change to 340mm

- Fully fiducial correction to ensure high alignment accuracy of PCB and stencil

- Windows operating system with simple programming wizard for ultra quick set-up

- Under stencil cleaner which is fully programmable and can be wet, dry and vacuum

- PCB support tooling and vacuum included

- SMEMA interface

- Quick product change over

- Intelligent squeegee system

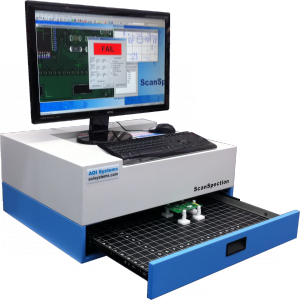

First Article Inspection -The FA-Inspector is a scanner-based optical inspection system used to automate first article inspections and subsequent production inspection tasks without programming. The FA-Inspector has two primary modes of operation: Comparator Mode and AOI Mode. Both AOI and Comparator Modes generate comprehensive reports complete with error location marks, fault classifications including the full PCB image or XY layout for easy rework. Reports can be viewed, printed, saved or emailed to customers for rapid prototype review. Defect coverage includes, all SMT and PTH parts down to 01005, part presence/absence verification, part polarity and pin #1 orientation, part position and skew errors, laser marking, wrong part and device differences such as: labels and colour variations.

The CAD import facility requires only basic placement Information such as Ref ID, Part No, Package Type, X, Y and rotation. Any adjustments to scaling, rotation, polarity and positioning can be adjusted using the correct fields in the CAD exchange file. An enhancement to this feature is the BOM comparison tool which allows you to import either the CAD or Pick and place info and then compare that information to the electronic BOM.

A file will then be created with any errors between the XY and BOM files, and an import file will also be created with the merged information, automatically making the perfect document for First Article Inspection

The layout viewer is another simple but very effective electronic tool that ensures that the inspection is being carried out is correct to not only to the BOM and XY Positions, but also polarity enabled devices have been placed in the correct orientation.

The software simultaneously displays the layout position and the position on the actual board, displaying the correct orientation and pin 1 position.

The PDF or JPG of the layout is loaded into the software, the XY information is then overlayed so that the actual board and the Layout file are the same size.

The Mega TSE3070T fully automatic SMT solder paste stencil printer provides a package of everything that is needed in a fully automatic in-line printer to produce high quality, high precision and high speed solder paste prints.

Key features:

- Fully adjustable in-line SMT solder paste printer

- Adjustable screen size (min 370mm x 370mm to 737mm / 29” x 737mm /29”

- Automatic conveyor width change to 340mm

- Fully fiducial correction to ensure high alignment accuracy of PCB and stencil

- Windows operating system with simple programming wizard for ultra quick set-up

- Under stencil cleaner which is fully programmable and can be wet, dry and vacuum

- PCB support tooling and vacuum included

- SMEMA interface

- Quick product change over

- Intelligent squeegee system

Our equipment is ideally suited to fast turnaround and low batch size production.

We utilise a methodology based on the best principles of Lean and World Class Manufacturing methods.

REQUEST A CALL BACK

Do you need further information on our products or services? Fill out this form to get in touch.